JUNNUO HDPE natural gas pipes are made from PE100 raw materials supplied by world-leading raw material suppliers such as Borealis, Shanghai Petrochemical, and Sinopec. The high toughness and light weight of polyethylene increases the cost-effective and reliable solution required for gas distribution systems.

HDPE gas pipe is suitable for outdoor gas transportation and distribution. The working temperature is between -20 °C and 40 °C, and the long-term maximum working pressure is not more than 0.7 MPa. JUNNUO HDPE gas pipes are ideal for low pressure gas delivery applications.

|

Name |

HDPE Natural Gas Pipes |

|

Size |

DN20-630mm |

|

SDR |

SDR11,SDR17.6 |

|

Material |

PE80, PE100, PE4710 |

|

Colors |

Yellow, Black or black with red strips |

|

Standard |

ISO 4437/ AS/ NZS 4130/ BS EN 1555/ SANS 8085 standard |

|

Remarkss |

Customers’ logo is available |

|

Sample |

Samples are available |

|

Packing |

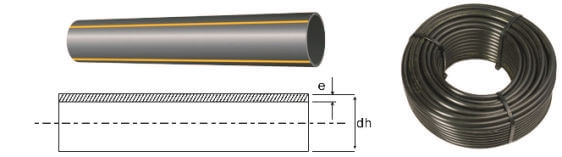

International standard packing

Less than 110 mm by rolls, more than 110 mm by length 5.8 m or 11.8 m. |

|

MOQ |

Negotiable |

|

Production |

Depending on the order quantity |

|

Certificates |

ISO 14001, ISO 9001, OHSAS 18001, CE BS EN 12201, WRAS certificates |

|

Warranty |

30 years for normal using |

|

Payment Term |

T/T or L/C at sight |

|

FOB Port |

Chongqing, Qingdao, Tianjin, Shanghai, etc |

|

Country of Original |

China |

We provide the HDPE gas pipes from DN20-630mm diameter with the SDR11 and SDR17.6 pressure rate.

|

Nominal Diameter |

Thickness(mm) |

|

|

|

SDR11 |

SDR17.6 |

|

20 |

2.3 |

2.3 |

|

25 |

2.3 |

2.3 |

|

32 |

3 |

2.3 |

|

40 |

3.7 |

2.3 |

|

50 |

4.6 |

2.9 |

|

63 |

5.8 |

3.6 |

|

75 |

6.8 |

4.3 |

|

90 |

8.2 |

5.2 |

|

110 |

10 |

6.3 |

|

160 |

14.6 |

9.1 |

|

200 |

18.2 |

11.4 |

|

250 |

22.7 |

14.2 |

|

315 |

28.6 |

17.9 |

|

400 |

36.3 |

22.7 |

|

500 |

45.4 |

28.4 |

|

630 |

57.2 |

35.7 |

Note: Special specifications can be customized. Please contact us for more product information and pricing.

Please send your request to the email address: ph@phpipefitting.com (We will respond to you within 24 hours).

HDPE natural gas pipes have the following advantages: